Reliance I Project: Innovation and Efficiency in Offshore Maintenance

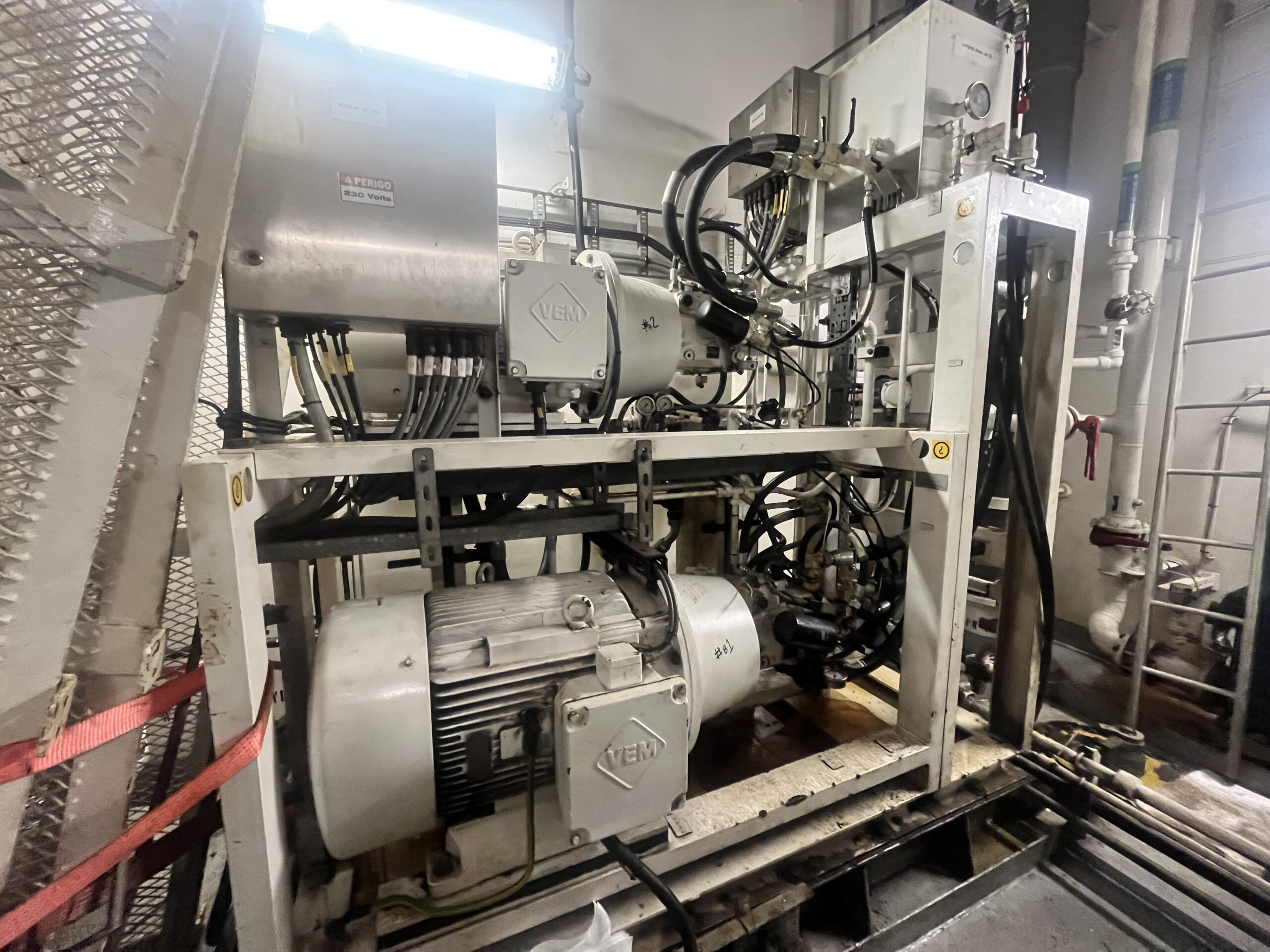

We were entrusted by Gran Energía with the execution of a critical maintenance project on board the Reliance I vessel. The scope involved the large-scale replacement of hydraulic hoses across essential operational systems, forming part of a broader maintenance campaign designed to safeguard the vessel’s long-term reliability, efficiency, and safety.

Within a challenging timeframe of less than three weeks, our offshore team mobilized and successfully completed the replacement of more than 700 hydraulic hoses distributed across multiple systems. This required a combination of precise planning, technical expertise, and seamless coordination with the vessel’s crew to minimize disruption to daily operations.

The work process covered the full cycle of intervention: identification and inspection of worn hoses, safe disassembly and removal of obsolete components, fabrication of custom-engineered replacements, precise installation, and final functional testing. Each stage was carried out with strict attention to detail and uncompromising quality standards, ensuring that every system was restored to optimal operational performance.

Health and safety were at the heart of this project. All tasks were executed in line with the vessel’s protocols and our own rigorous standards, including permit-to-work systems, confined space entry procedures, and mandatory use of personal protective equipment (PPE). Thanks to this disciplined approach, the project was delivered with zero incidents.

Beyond the technical scope, this project represents a milestone in TESS Canarias’ ability to deliver rapid, large-scale offshore solutions. It demonstrates our proven capacity to mobilize specialized teams, adapt to complex operational environments, and consistently provide results that meet and exceed client expectations.

At TESS Canarias, we remain committed to supporting our clients in the most demanding offshore environments, offering reliable maintenance solutions that combine technical excellence, safety, and efficiency.

Scope of work

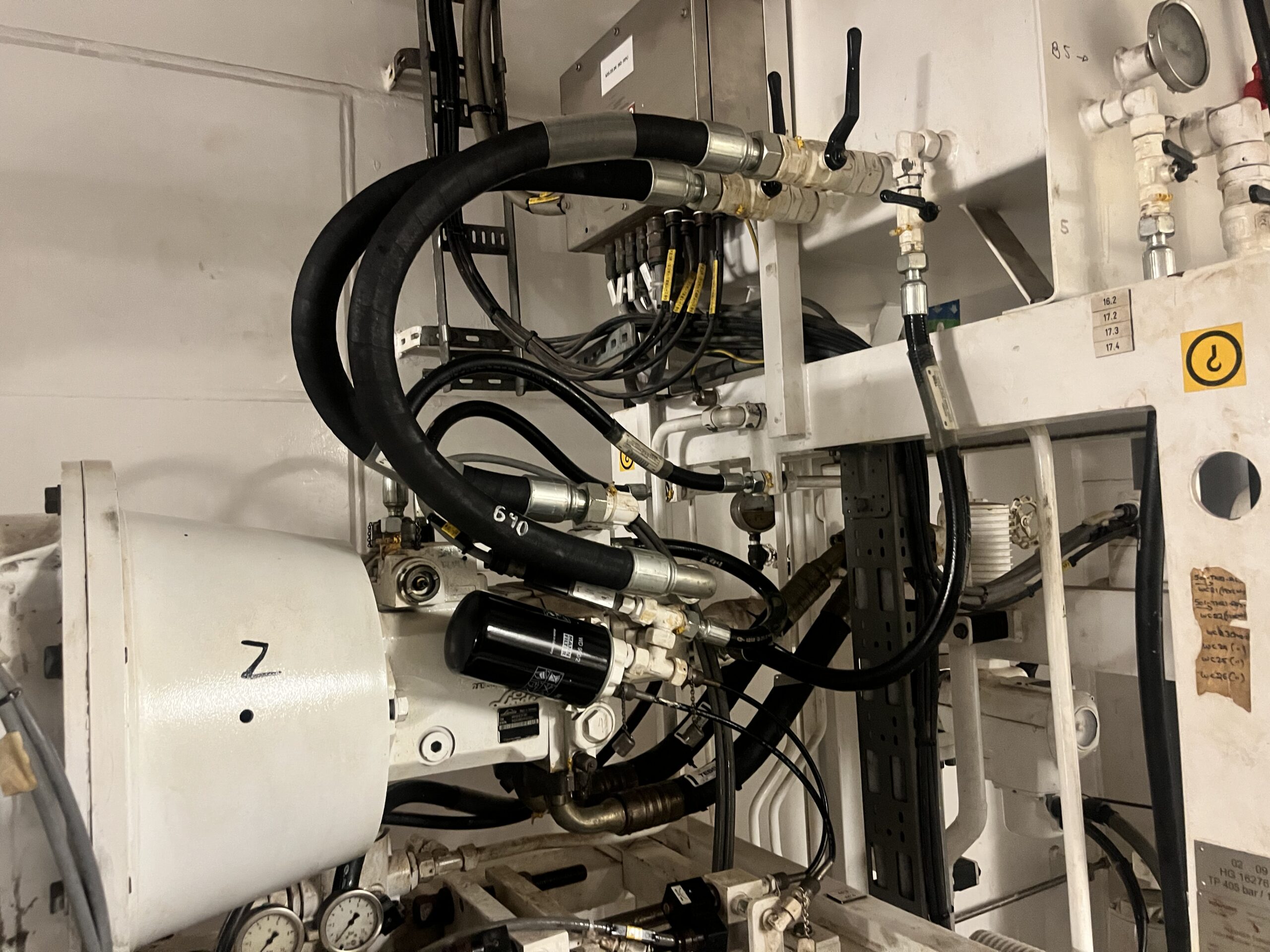

Our SOW has followed guidelines to perform the work with the highest efficiency, safety and quality. Each hose that was replaced was capped and drained to prevent oil spillage. The manufacture of the new hoses followed a quality procedure that includes:

- Cleaning of the hose cut with projectiles

- Pressing according to manufacturer’s tables

- Pressure testing to 1.5 WP

- Labelling of each hose with the related information

- Capping of each end to prevent dirt ingress

The installation of each hose has been carried out by double checking to avoid that no hose is left without the necessary tightening.

Once installed, the corresponding test was carried out on the equipment to correct possible leaks in case they exist.

Finally, each terminal was covered with dense tape to prevent corrosion.